Variable Inkjet Systems for Corrugated & Flexible Packaging

Add Variable Data to Packaging Lines Without Replacing Equipment, Speeds Up to 1,200 FPM

Packaging manufacturers face increasing demand for customization, serialization, and variable product information—all while maintaining production speed. DPi's industrial variable inkjet systems integrate inline with corrugators, folder-gluers, bag machines, and converting equipment to print lot codes, expiration dates, QR codes, and promotional content at speeds up to 1,200 FPM.

Our systems retrofit to existing packaging lines rather than requiring complete equipment replacement, delivering variable data capability at a fraction of digital press costs. Whether you're printing on corrugated board, flexible film, folding cartons, or bags, our UV and water-based inkjet solutions handle the substrate challenges unique to packaging operations.

Our goals for you:

Design and build customized high-speed Inkjet printing machines for Corrugated Packaging

Any width / speeds over 1000 fpm

Comparable printing costs to Flexo Post Print + the advantages of digital printing

Lower capital costs

Retrofit existing corrugated converting equipment

Stand-alone printing equipment

Packaging Applications for Variable Inkjet

Corrugated Box Printing

Common Applications:

Print variable data directly on corrugated boxes inline with your corrugator, folder-gluer, or converting equipment. Our systems integrate at the wet-end web or constructed-end, handling widths from 4" to 130" with speeds up to 1,200 FPM.

Lot codes and batch numbers for traceability

Expiration dates for food and beverage products

QR codes for consumer engagement and authentication

Shipping information (addresses, routing codes)

Regional versioning (different distributors, languages, markets)

Promotional campaigns (seasonal messaging, limited editions)

Serialization for track-and-trace compliance

Flexible Packaging

Add variable data to flexible packaging films, bags, and pouches inline with bag-making machines, form-fill-seal equipment, and flexible packaging converters.

Common Applications:

Product dating (best by, use by, manufactured on)

Lot and batch tracking for food safety compliance

Promotional codes for consumer engagement

Multi-SKU runs without changeover delays

Regional product information (multilingual, distributor-specific)

QR codes linking to recipes, instructions, promotions

Folding Cartons & Retail Packaging

Print variable product information on folding cartons for food, beverage, pharmaceutical, cosmetic, and consumer goods packaging.

Common Applications:

SKU versioning (sizes, flavors, variants)

Batch and lot codes for compliance

Expiration dating inline with production

Promotional versioning (limited editions, seasonal campaigns)

Retailer-specific packaging without inventory waste

GS1 barcodes for retail scanning

Bag Printing (Paper & Poly)

Integrate variable inkjet with bag-making equipment for shopping bags, food bags, industrial bags, and specialty packaging.

Common Applications:

Customer-specific branding (retail chains, distributors)

Variable messaging for promotional campaigns

Product information (weight, contents, handling instructions)

Batch tracking for industrial applications

DPi Packaging Inkjet Systems

Custom Corrugated Inkjet Systems

For Corrugators, Folder-Gluers, and Die-Cutters

Our custom corrugated systems are engineered for your specific equipment, substrate, and production requirements. We design mounting solutions for nearly any corrugator or converting equipment.

Key Features:

Print widths: 4" to 130" (scalable with multiple printheads)

Speeds: Up to 1,200 FPM

Ink types: UV-curable, water-based

Colors: Monochrome or CMYK configurations

Integration: Wet-end, dry-end, or post-converting

Substrates: B-flute, C-flute, E-flute, double-wall, triple-wall

Equipment We Integrate With:

BHS Corrugators

Fosber Corrugators

Marquip Converting Equipment

Asitrade Systems

Martin Automatic Splicers

Bobst Die-Cutters

Any rotary or flatbed folder-gluer

Substrate Compatibility:

Polyethylene (PE) film

Polypropylene (PP) film

PET (polyester) film

Foil laminations

Paper-based flexible packaging

Stand-up pouche

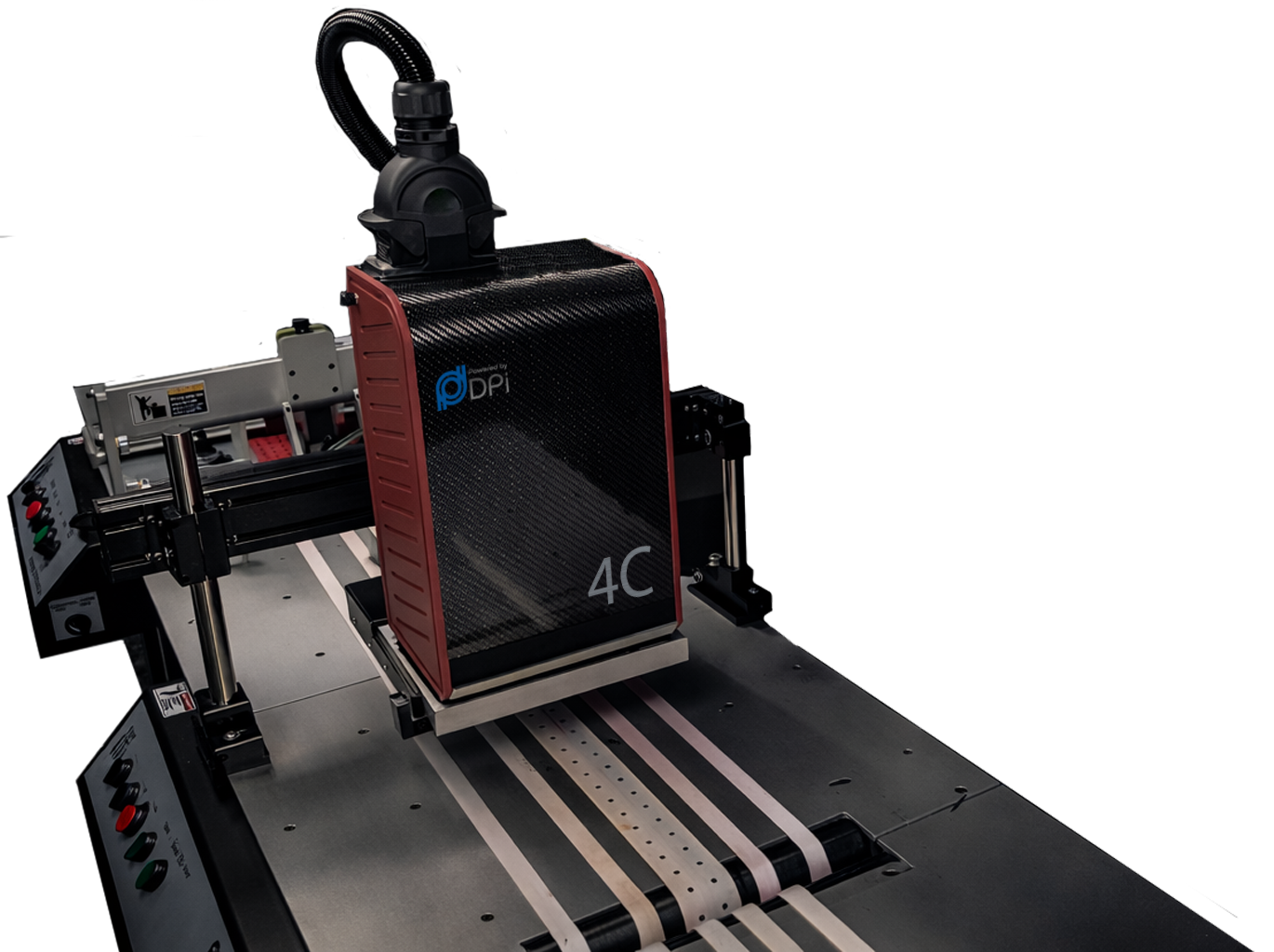

Hawk 4-Color System (High-Resolution Packaging Graphics)

For Variable Color Packaging and Promotional Campaigns

The Hawk 4C delivers 1200 DPI full-color variable printing for packaging applications requiring photographic quality or full-color personalization.

Key Features:

Resolution: 1200 DPI native

Colors: Full CMYK

Applications: Promotional packaging, personalized campaigns, high-graphic retail packaging

Lower cost than digital presses for short-run color

Benefits of DPi Packaging Inkjet Systems

1. Eliminate Pre-Printed Inventory

Print variable product information on-demand instead of maintaining warehouses of pre-printed boxes. Reduce inventory costs, minimize obsolescence, and gain SKU flexibility.

2. No Changeover Delays

Switch between SKUs, lot codes, or product versions instantly—no plate changes, no setup time, no production stops.

3. Lower Capital Investment

Retrofit existing equipment for $75,000-$250,000 instead of spending $500,000+ on a digital press.

4. Production Speed Maintained

Print variable data at full line speed—up to 1,200 FPM on corrugators. No slowdowns or bottlenecks.

5. Substrate Versatility

UV inks work on corrugated board, film, foil, bags—substrates that digital presses struggle with.

6. Scalable Configuration

Start with one printhead and expand to full-width coverage as volume grows. Modular systems allow incremental investment.

7. USA Engineering & Support

Designed and manufactured in Texas with fast support response, no overseas delays, and direct access to engineers.

Packaging Industry Trends Driving Variable Data Adoption

1. E-Commerce Growth

Online retail demands customized shipping boxes with variable addressing, tracking codes, and branded packaging. Variable inkjet enables on-demand box printing without inventory waste.

2. Brand Personalization

Consumer brands use variable packaging for promotional campaigns, limited editions, and personalized products. Regional versioning allows different messaging by market without separate production runs.

3. Serialization & Track-and-Trace

Pharmaceutical, food, and consumer goods manufacturers face increasing serialization requirements. Variable inkjet prints unique codes on every package for compliance and supply chain visibility.

4. Sustainability

On-demand variable printing reduces packaging waste by eliminating obsolete pre-printed inventory. Print only what you need, when you need it.

5. Just-in-Time Manufacturing

Modern packaging operations demand flexibility. Variable inkjet allows rapid SKU changes without setup time, supporting lean manufacturing principles.

Related Resources

Systems:

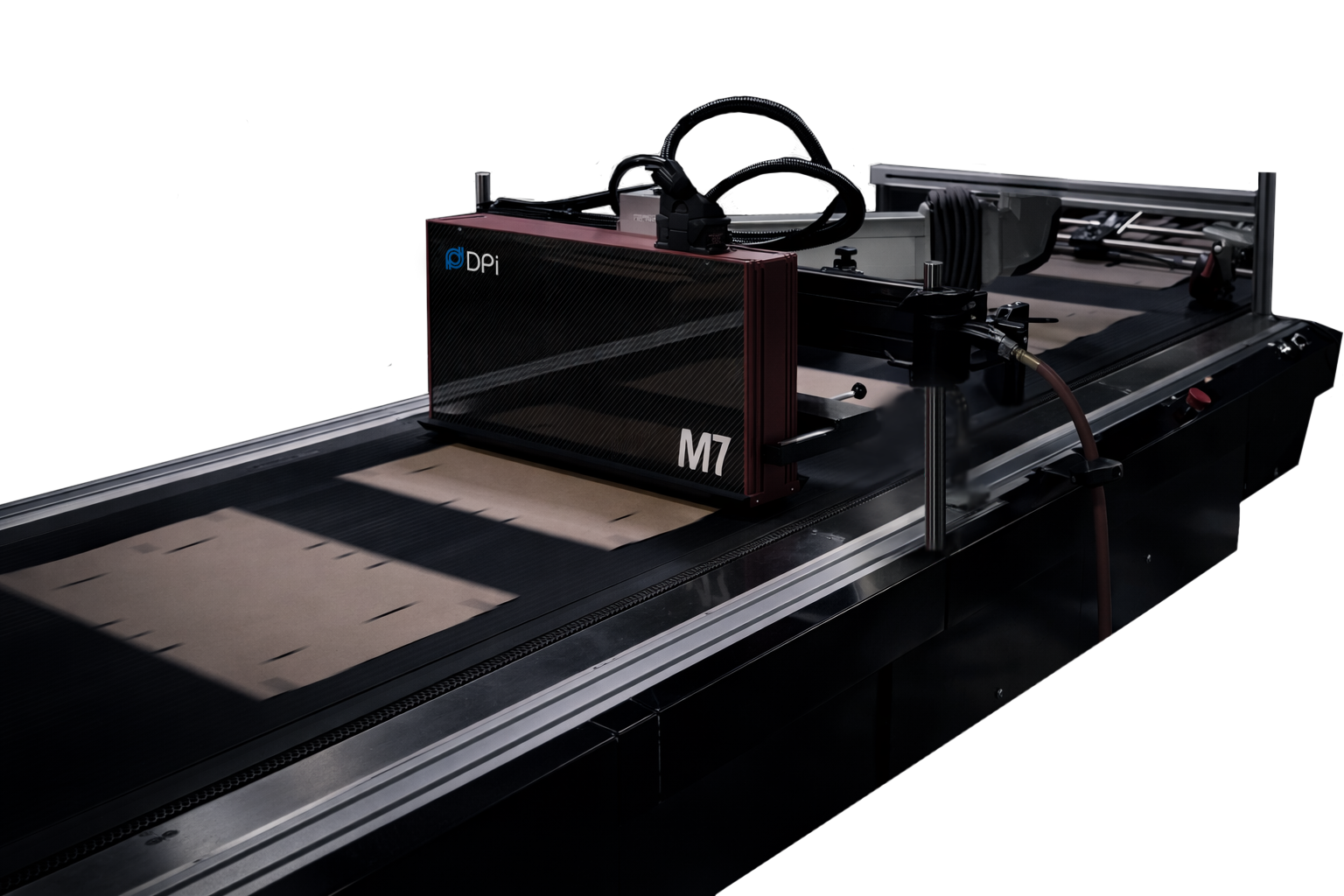

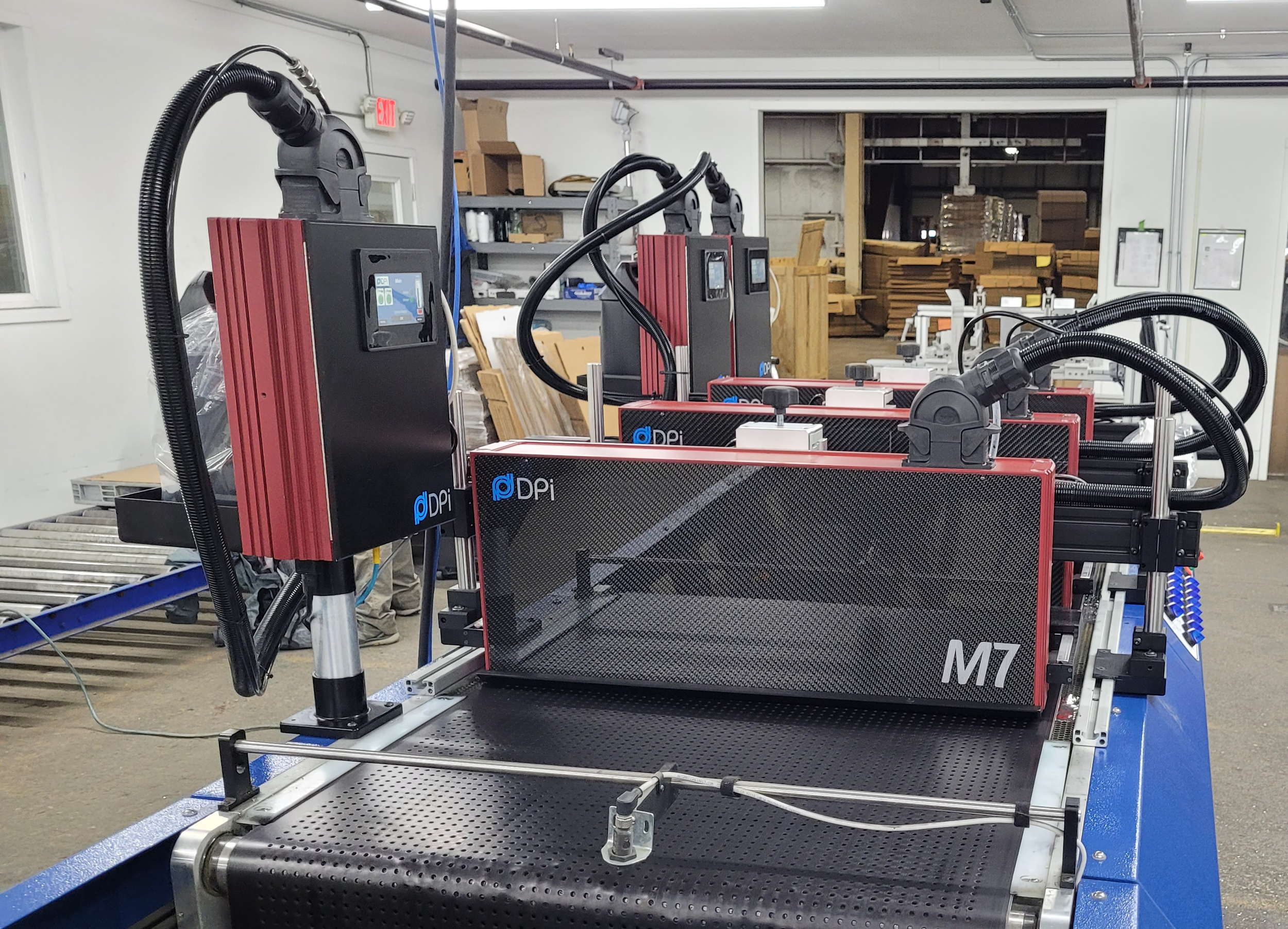

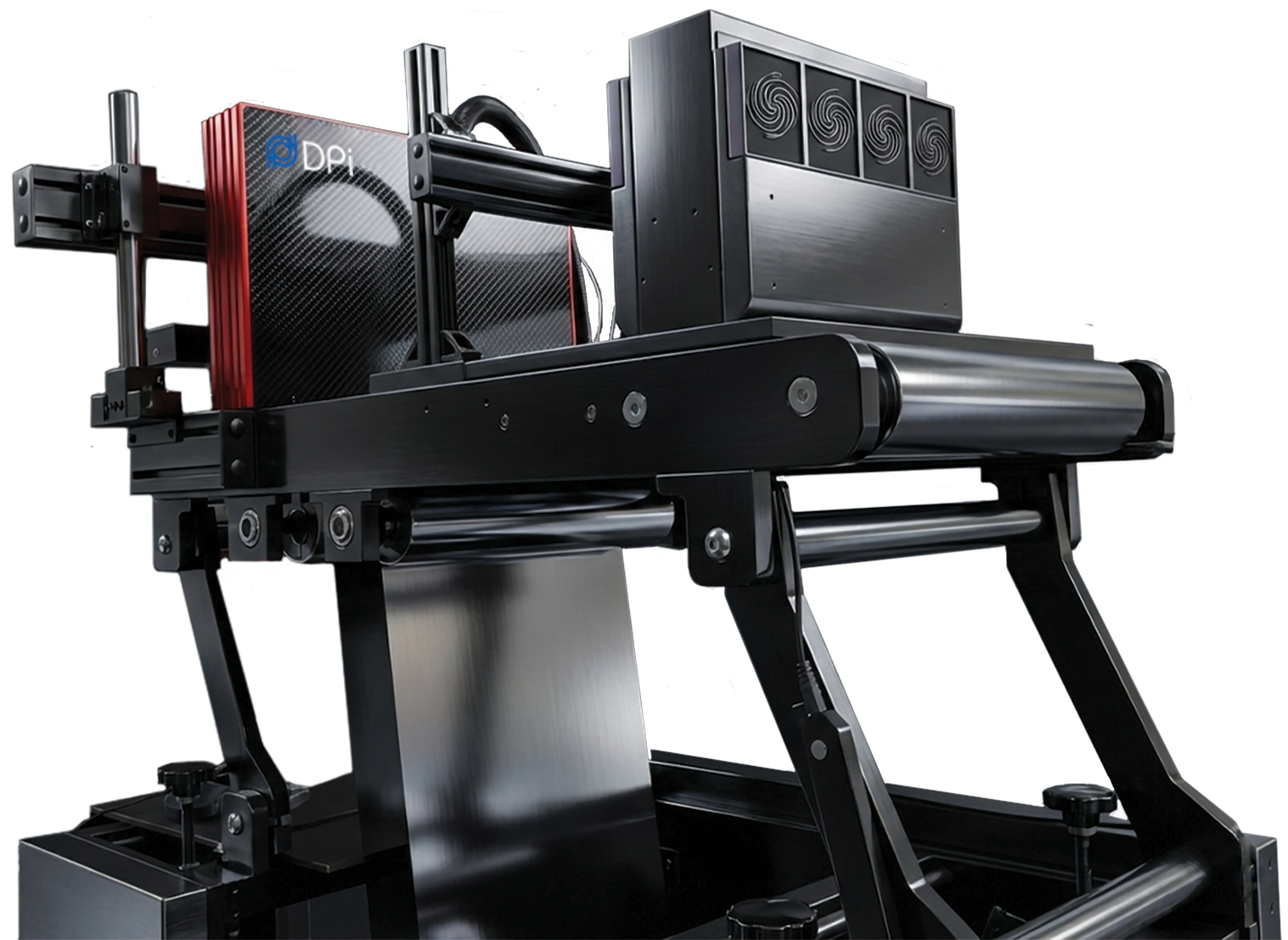

M7 Variable Web System - For flexible packaging and film

Hawk 4-Color System - For high-resolution color packaging

Code Reading Systems - Barcode verification for compliance

Applications:

Variable Data Printing Solutions - Overview of all applications

Label Printing Systems - Narrow-web label integration

Direct Mail Addressing - High-speed addressing systems

Industry Insights:

Get Started with Packaging Variable Inkjet

Ready to add variable data capability to your packaging line? Whether you're a corrugated converter, flexible packaging operation, or folding carton manufacturer—DPi has a solution.

Next Steps:

Request Specifications: Get detailed system specs for your application

Schedule Consultation: Speak with our packaging integration engineers

Site Survey: We visit your facility to assess integration requirements

Custom Proposal: Receive engineered solution with pricing and timeline

Contact DPi Packaging Solutions:

📞 (817) 512-3151

📧 sales@digitalprint.com

📍 217 Performance Ln, Cresson, TX 76035

M7 Variable Web System (Flexible Packaging)

For Bag Machines, Form-Fill-Seal, and Film Converters

The M7 Web system integrates with flexible packaging equipment to print variable data on film, foil, and flexible substrates at production speeds.

Key Features:

Print widths: 4.25" to 26.4"

Speeds: Up to 1,000 FPM

Inks: UV LED instant-dry (works on non-porous films)

Resolution: 300-600 DPI

Substrates: PE, PP, PET film, foil, laminates

Applications:

Food packaging (snacks, frozen foods, produce)

Pet food bags

Industrial packaging

Stand-up pouches

Pharmaceutical packaging

Frequently Asked Questions

What types of packaging can DPi systems print on?

DPi systems print on corrugated boxes, flexible packaging films (PE, PP, PET), folding cartons, bags (paper and poly), and specialty substrates like foil and metalized films. Our UV inks handle both porous (paper, board) and non-porous (film, foil) substrates.

How fast can packaging inkjet systems run?

DPi systems print at speeds up to 1,200 FPM on corrugated lines and up to 1,000 FPM on flexible packaging equipment. Speed depends on resolution, substrate, and ink type.

Can variable inkjet replace flexo or offset printing on packaging?

Variable inkjet is designed to add variable data (lot codes, dates, QR codes) to packaging that already has base graphics from flexo, offset, or litho printing. For full-color process printing, our Hawk 4C system offers an alternative for short-run or variable-color applications.

How does variable inkjet integrate with corrugators?

We design custom mounting solutions for your specific corrugator model. Integration can happen at the wet-end (before cutting), dry-end (after corrugating), or post-converting (on folder-gluers or die-cutters). We've integrated with BHS, Fosber, Marquip, and most major corrugator brands.

What's the difference between UV and water-based inks for packaging?

UV inks cure instantly under UV light, making them ideal for non-porous substrates (film, foil, coated board) and high-speed applications. Water-based inks work on porous substrates (uncoated paper, kraft board) and are preferred for some food-contact applications. We recommend ink type based on your substrate and regulatory requirements.

Can I print full-width on corrugated board?

Yes. Our systems scale from 4" to 130" print width by adding multiple printheads. For wide corrugators, we configure systems with 10-30 printheads to cover full board width.

How long does installation take?

Installation time depends on integration complexity. Standalone systems install in 1-2 days. Inline corrugator integration typically takes 3-5 days including mechanical mounting, electrical connection, and software setup. We provide on-site installation and operator training.

What maintenance do packaging inkjet systems require?

Routine maintenance includes daily nozzle checks, weekly cleaning, and printhead replacement at end of life (~8,500 hours). Printheads are modular and field-replaceable. Most customers perform maintenance in-house after initial training.

Can I print GS1 barcodes for retail packaging?

Yes. Our QPress software generates all standard barcode formats including UPC, EAN, GS1-128, Data Matrix, and QR codes. Barcodes are automatically sized and formatted to meet retail scanning requirements.

Do you offer barcode verification for packaging?

Yes. Our Code Reading System (CRS) scans and verifies every barcode in real time, ensuring 100% readability before packages leave the line. CRS is critical for pharmaceutical serialization, food traceability, and retail compliance.

What file formats does QPress accept for packaging jobs?

QPress accepts Excel, CSV, SQL databases, and other standard formats for variable data. For graphics, we support PDF, TIFF, EPS, and AI. Most packaging operations provide data as spreadsheets or database exports.

Can I run multiple SKUs without stopping production?

Yes. Variable inkjet allows instant SKU changes without plate swaps or setup time. Switch from one product code to another mid-run by simply loading a new data file.

Where are DPi packaging systems manufactured?

All DPi systems are designed, engineered, and manufactured in Cresson, Texas, USA. This allows for custom configurations, rapid support response, and direct communication with our engineering team.

How do I get started?

Contact us to discuss your packaging type, substrate, production speed, and variable data requirements. We'll recommend system configuration, provide specifications, and arrange a site visit or factory demonstration.